Use cases

One system for all your hands-on engineering

Fusion lives with your designers, engineers, assemblers, and specialist makers so they can deliver great hardware to your customers.

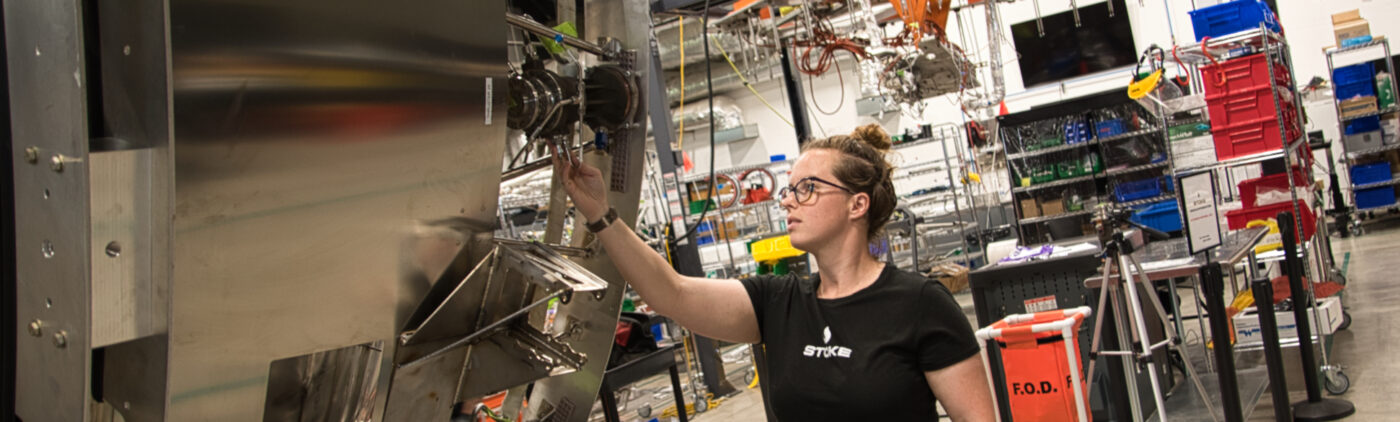

Stoke Space

Industry:

Aerospace

Team Size:

100+ Fusion users

The Challenge

Building rockets is no easy task, and it normally takes years to get to orbit. In order to compete with rocket companies already in production, Stoke needed to go extra fast. As rocket industry vets, the founders knew that configuration management would be a massive friction, if they didn’t have a better solution.

See how three Stoke employees with different responsibilities utilize Fusion to get their jobs done better and faster.

Jenna

Responsible Engineer

Responsibility

I am the responsible engineer for the stage two combustion devices. I am in charge of taking thrusters from design through procurement, assembly, and service.

How Fusion helps

Fusion allows me to track thruster units installed in development and production hardware at the same time. Workflows tell me every step of unit manufacturing from first machining, cleaning and inventory, through final assembly and service. Whenever we need to define non-conformance procedures, we can add them and track discrepancies for any component. These records live with the hardware so we can verify configurations on the shop floor or on the test stand.

Nico

Manufacturing Engineer

Responsibility

I am the Stage 1 Engine (S1E) integrated design lead. Basically, my job is to take the major pieces and components we design and ensure they can integrate into a full engine unit. That means creating many types of interfaces, including tubes, brackets, and sensors.

How Fusion helps

Fusion helps me translate my CAD designs into real hardware, even if that hardware is produced by many different people. New designs synch from PLM in minutes, so Fusion has all the details of parts and assemblies. I can then create inventory steps and trigger shop orders. Since all our technicians work in the same system, we can exchange feedback clearly and consistently. We can roll out improvements on the fly.

Rob

Manufacturing Technician

Responsibility

I work across multiple functions including inventory, assembly, and testing, so I need to make sure the right parts move to the right places and people. Parts are always in motion here. Our rocket components always evolve, and we need keep up with changes.

How Fusion helps

Fusion has made handling thousands of parts super easy. The moment a part arrives, I can confirm it’s pulled into the correct process. Some parts are for stock, but others move directly into waiting assemblies. Many parts we make in-house need special treatment (like cleaning) or documentation, and Fusion prevents errors and misses. Anytime we need to question a part, we can just scan a QR code. Fusion stops guesswork.